It is one of the post-harvest processes that most affects the quality of the products obtained from cocoa. During fermentation, the pulp is degraded by the action of microorganisms, which causes the temperature to rise, the production of ethanol, lactic acid and acetic acid. This process results in the formation of chocolate flavor and aroma precursors, which will develop during the roasting process. Completely fermented beans have a dark brown color.

Without fermentation, cocoa does not develop the desired flavor characteristics during roasting.

There are different fermentation methods, the most common being: wooden crates, rumas or piles and in bags, either jute or polypropylene; However, the best results in the quality of the final product are obtained in wooden crates.

The number of days of fermentation cannot be generalized, it depends on the genetic material, the fermentation method and the quantity to be fermented. Generally the Creole type needs 3 to 4 days; The Trinidadian type requires between 5 to 6 days and the foreign types need 5 to 8 days. It is also important to establish the relationship with the other environmental factors that characterize each producing area.

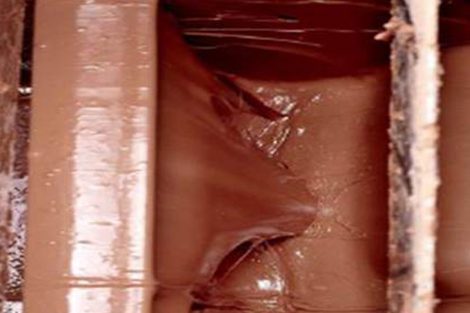

An indicator of satisfactory fermentation is the presence of a peripheral ring of brown color, indicating that the cocoa should begin to be spread for drying.

Furthermore, when a cross section of the grain is made, a characteristic cracking of the fermented grain is observed and it has a chocolate flavor.